Capacity to 2000 m³/h (8800 GPM),

max pressure 16 bar (535 feet) at 50Hz.

Capacity to 2200 m³/h (9690 GPM),

max pressure 6 bar (535 feet) at 60Hz.

TCH SERIE

Technical information

The new pumps series TCH and derived series of the same family, reflect the design guidelines given by ISO 5199 class II standards: these norms provide for

the introduction of new and severe manufacturing standards applicable to the pumps manufactured according to ISO 2858/DIN 24256 standards in order to

get an ideal product for the heaviest uses, especially in the petrochemical industry, following the example of API standards.

These pumps are also the results of Pompetravaini’s continuous research and development, of the extensive experience acquired over many years with the

previous series MCU-CH applied in numerous installations and fields. Finally we believe these pumps reflect the many suggestions and opinions received from

our vast clientele and users.

The TCH pump series is an extremely improved product for:

• Toughness

• Efficiency

• Reliability

• Safety

• Durability

• Lower operating costs

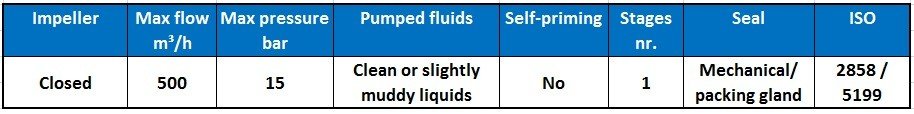

The manufacturing program includes three bearing frame sizes of the “Back pull-out” type, the pump casing is of the spiral type with axial suction flange, the

impeller is of the radial type with overhang mounting.

All our production is guaranteed by certified quality system according to ISO 9001:2000 standards.

Handling clean or slightly contaminated liquids, hot, superheated, acidic and caustic in

chemical industry, petrochemical, pharmaceutical, food, pulp and paper, environmental, steel,

textile, etc.

• Capacity up to 500 m3/h and heads to 16 bar.

Overall dimensions and performances are in accordance to standards ISO 2858/DIN 24256

Materials of construction are numerous, from cast iron to

hastelloys.

• High hydraulic efficiencies and low NPSH requirements.

• Shaft sealing by packed stuffing box, single or double mechanical

seals (ISO 3069/UNI EN 12756) with every installation option

per API requirements.

• Pump casing and seal housing can be provided with heating or

cooling chambers, as needed.

• Units up to 30 kW size can be close coupled, with the addition

of a support lantern, to motors with B5 flange. This monoblock

design offers great alignment advantages, simplicity of assembly

and guarantee of perfect alignment even after transportation.

• From the TCH series have derived series TCT, TCA and TCD that are

designed for very specific pumping applications; all these series utilise many common components.

Typical cross section and variants

For lighter duty applications it is possible to have the pump with two ball bearings and smaller shaft diameter that nevertheless, still guarantees reliability

and toughness.

This type of rotor support (shaft and bearings) is equal and interchangeable with the previous series MCU-CH and the pump has all the benefits from the TCH

series with a lower initial cost (available for group 1 and 2 only).

Monostage centrifugal pumps with closed impeller according to ISO 2858 & 5199 (series TCH).

Capacity to 2000 m³/h (8800 GPM),

max pressure 16 bar (535 feet) at 50Hz.

Capacity to 2200 m³/h (9690 GPM),

max pressure 6 bar (535 feet) at 60Hz.

Monostage centrifugal pumps with closed impeller according to ISO 2858 and 5199