The new hydraulic profile allows a performance increase over 10% than the traditional liquid ring vacuum pump designs.

Increases the efficiency and operational cost savings all over the entire pump life.

The pump weight is average 30% less compared with the

traditional liquid ring vacuum pump designs with compact

supporting components dimensions. This advantage allows

installation and transportation costs saving.

Compact dimensions and volume

(L x W x H) 50% less compared with

the traditional liquid ring vacuum pump

designs. Optimization of factory or plant

installation spaces and related costs saving.

Single and direct service liquid connection. Easy pump fitting without the use of complicate piping. This ensures a fast

and economic pump installation.

Central body impeller housing with integrated suction and discharge manifolds with compact overall dimensions. This feature

reduces pump components and increases robustness. The maintenance and assembly time and costs saving result to be greatly

advantaged

The suction and discharge port plates are always in stainless steel allowing a greater reliability trough the time and

ensuring stable performances. They never require to be replaced during ordinary maintenance reducing down the spare parts cost.

Liquid ring vacuum pumps series

TRMX

The TRMX series is the transfer of all the TRVX series basic concepts on the monoblock pumps production. The result is an

economical pump with outstanding performance and reliability.

The new hydraulic profile design allows a performance increase from 10% to 20% compared with previous series.

This increases the efficiency and operational cost savings all over the entire pump life.

Compared with the previous TRMB series, the TRMX is 10% lighter. The volume is 10-20% smaller. These two

features permit fast and less expensive installations.

Maximum flexibility for handling the sealing

liquid. In std. condition the TRMX series

requires up to 40% less

sealing fluid flow

compared with the

previous TRMB series,

ensuring a big saving

in the operating cost.

In the applications

where is required the

possibility to aspirate

big sealing liquid flow,

pumps are supplied with

enhanced higher sealing

liquid flow capability.

Inox port plate with laser cut port profiles. This solution make the port plate free from wear and the laser cut ports guarantee

the execution of the best performing designed profiles. Very noticeable the increase of the pump working economy.

Innovative anti-cavitation system derived from the TRVX series. The injection port is located very close to the

suction port improving the highest operational vacuum level and guarantee higher efficiency all over the pump

vacuum range. With this solution the pump operational cost is reduced 2 in a sensible way.

Single stage liquid ring vacuum pumps of new concept.

Capacity to 1650 m³/h (970 ACFM),

max vacuum 33 mbar (28.95 "HgV / 25 Torr) at 50 Hz.

Capacity to 2000 m³/h (1150 ACFM),

max vacuum 33 mbar (28.95 "HgV / 25 Torr) at 60 Hz.

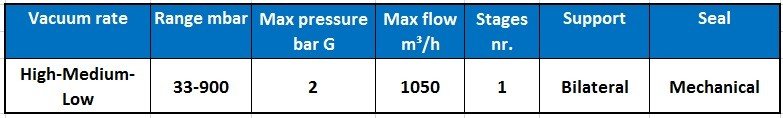

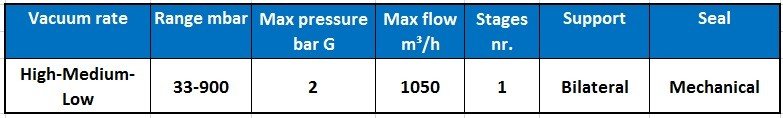

Monostage liquid ring vacuum pumps for high, medium and high vacuum

Monostage liquid ring vacuum pumps for high, medium and high vacuum